Moulded Pulp Fitments

Moulded pulp packaging represents a forward-thinking approach to eco-friendly solutions, crafted not only from recycled materials but also from 100% virgin fibres, primarily sourced from sugarcane. This sustainable option is both cost-effective and environmentally responsible, making it an ideal choice for businesses looking to reduce their carbon footprint. The production process utilises the natural strength of sugarcane fibres, resulting in packaging that offers exceptional protection for delicate items. Its biodegradable and compostable nature ensures that it leaves minimal impact on the planet. Moulded pulp is versatile, suitable for a wide range of applications, from electronics to food products. By opting for this innovative packaging solution, companies can demonstrate their commitment to sustainability while providing their customers with reliable and attractive packaging that meets modern environmental standards.

Moulded Pulp Boxes

Moulded pulp boxes are an innovative solution that not only serve as fitments within rigid boxes but can also function as standalone packaging. Crafted from recycled materials, these eco-friendly boxes provide excellent protection for your products while showcasing a sustainable approach to packaging. The production lead time for a first run is approximately 6 to 9 months, with reorder times significantly shorter at around 1 to 3 months. Pricing is flexible, starting from just a few euros for orders of 10,000 units, with costs decreasing further to less than a euro for larger quantities. This makes moulded pulp boxes not only a practical choice but also a cost-effective one for businesses looking to enhance their packaging strategy.

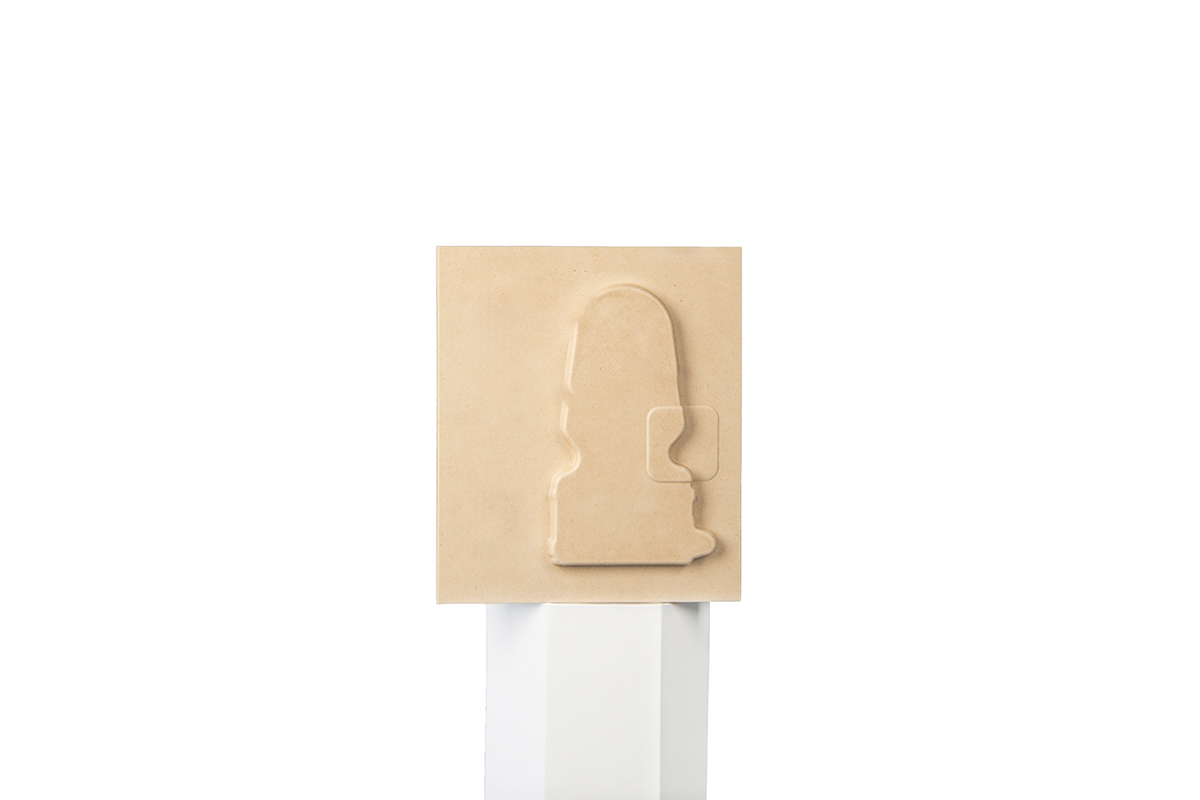

Bespoke Pulp Fitments for Rigid Boxes

Our bespoke pulp fitments are expertly crafted from 100% virgin fibre, and can be produced in various sizes and types to perfectly suit your rigid boxes. With a minimum order quantity of just 10,000 units, our pricing ranges from 1 to 3 euros, making it an economical choice for your packaging needs. For larger orders of 50,000 to 100,000 units, the cost drops to less than a euro each, providing exceptional value. Reordering is even more cost-effective as tooling costs are excluded, ensuring you save on future purchases. Our fitments are produced using both wet and dry press techniques, guaranteeing durability and a perfect fit for your products.

Wet Pressed Moulded Pulp Fitment

Experience the perfect blend of sustainability and quality with wet-pressed moulded pulp fitments crafted from 100% virgin fibre. These premium packaging solutions are designed to enhance the presentation of your products while showcasing your dedication to eco-conscious choices. With a minimum order quantity of 10,000 units, pricing starts at around 1 to 3 euros for the MOQ, inclusive of tooling costs. Future orders benefit from significantly lower tooling expenses, while 3D samples or models are available at an additional cost. Transform your packaging strategy with a refined and environmentally friendly option.

Dry Pressed Moulded Pulp Fitment

Discover the exceptional quality of dry-pressed molded pulp fitments that elevate your product packaging to new heights. Made from premium materials, these fitments not only provide a stunning presentation but also reflect your commitment to sustainable practices. With a minimum order quantity of 10,000 units, you can expect competitive pricing between 1 to 3 euros, which includes tooling costs. Enjoy the benefits of faster and more economical reorders, ensuring your packaging needs are met efficiently. Additionally, we offer 3D model samples to help you visualize your design before production. Choose dry-pressed molded pulp fitments for a sophisticated and eco-friendly packaging solution.

Moulded Pulp Boxes

Moulded pulp boxes are an innovative solution that not only serve as fitments within rigid boxes but can also function as standalone packaging. Crafted from recycled materials, these eco-friendly boxes provide excellent protection for your products while showcasing a sustainable approach to packaging. The production lead time for a first run is approximately 6 to 9 months, with reorder times significantly shorter at around 1 to 3 months. Pricing is flexible, starting from just a few euros for orders of 10,000 units, with costs decreasing further to less than a euro for larger quantities. This makes moulded pulp boxes not only a practical choice but also a cost-effective one for businesses looking to enhance their packaging strategy.

Bespoke Pulp Fitments for Rigid Boxes

Our bespoke pulp fitments are expertly crafted from 100% virgin fibre, and can be produced in various sizes and types to perfectly suit your rigid boxes. With a minimum order quantity of just 10,000 units, our pricing ranges from 1 to 3 euros, making it an economical choice for your packaging needs. For larger orders of 50,000 to 100,000 units, the cost drops to less than a euro each, providing exceptional value. Reordering is even more cost-effective as tooling costs are excluded, ensuring you save on future purchases. Our fitments are produced using both wet and dry press techniques, guaranteeing durability and a perfect fit for your products.

Wet Pressed Moulded Pulp Fitment

Experience the perfect blend of sustainability and quality with wet-pressed moulded pulp fitments crafted from 100% virgin fibre. These premium packaging solutions are designed to enhance the presentation of your products while showcasing your dedication to eco-conscious choices. With a minimum order quantity of 10,000 units, pricing starts at around 1 to 3 euros for the MOQ, inclusive of tooling costs. Future orders benefit from significantly lower tooling expenses, while 3D samples or models are available at an additional cost. Transform your packaging strategy with a refined and environmentally friendly option.

Dry Pressed Moulded Pulp Fitment

Discover the exceptional quality of dry-pressed molded pulp fitments that elevate your product packaging to new heights. Made from premium materials, these fitments not only provide a stunning presentation but also reflect your commitment to sustainable practices. With a minimum order quantity of 10,000 units, you can expect competitive pricing between 1 to 3 euros, which includes tooling costs. Enjoy the benefits of faster and more economical reorders, ensuring your packaging needs are met efficiently. Additionally, we offer 3D model samples to help you visualize your design before production. Choose dry-pressed molded pulp fitments for a sophisticated and eco-friendly packaging solution.

Molded Pulp Fitments

As a premier supplier of moulded pulp fitments, we take pride in offering a wide variety of options that serve as both fitments for rigid boxes and standalone packaging solutions. Our fitments are meticulously crafted from 100% virgin fibres, ensuring that they meet the highest standards of quality and sustainability. When it comes to lead times, first-time orders typically require between 3 to 9 months for production, while reorders are generally fulfilled in approximately 1 to 3 months. We maintain a minimum order quantity of 10,000 pieces to ensure efficiency and cost-effectiveness. Pricing for our fitments starts at around 2 to 3 euros per unit when tooling is included, and approximately 1 euro per unit when tools are not required. For larger orders, such as those exceeding 50,000 or 100,000 pieces, the price can drop to below 1 euro per unit, making it an economical choice for bulk purchases. Please keep in mind that these prices are approximate and intended to provide a general idea for our clients.